The aerospace and automotive industries are only two of several that use titanium milling to make stronger, more long-lasting products. Further information on how the titanium milling process may help your business follows.

What Is Titanium Milling?

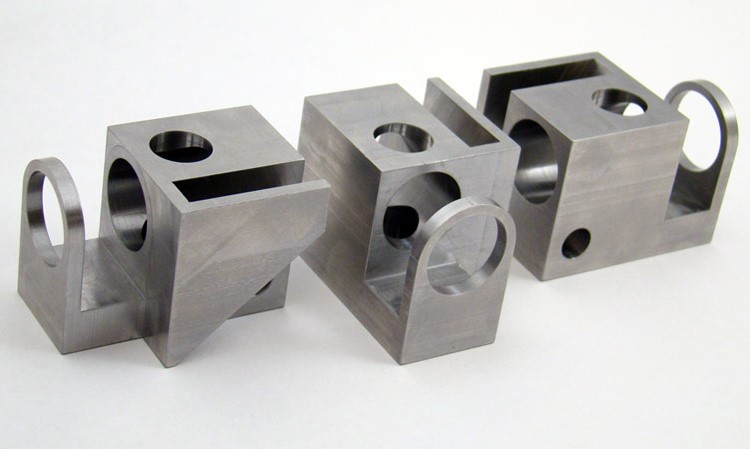

In milling, titanium is drastically reduced; the resultant pieces are put together in a jigsaw-puzzle fashion. This technique is used to create titanium alloys with various compositions, which have several applications. Titanium mills may also forge alloys and other metals.

The automotive industry is the single largest consumer of titanium mills. Titanium alloys are widely used in the car industry because of their resistance to heat and pressure, and they are both lightweight and sturdy, which makes them great for use in vehicles.

Additionally to titanium, other metals and alloys may be treated in titanium mills. Examples include the widespread usage of titanium nitride in aerospace applications due to the material's high resistance to corrosion. Forging aluminum and other metals is possible in titanium forges.

And How Exactly Does It Work?

The first stage in making titanium mills is to acquire a slab of titanium that has already been shaped and cut to specification. After that, the titanium is chopped into pieces of consistent size using a machine. This process is essential to ensure uniformity in size and shape among the titanium parts.

Once the titanium has been formed, it is sent to the slag pot as a massive metal bucket on top of the furnace. To achieve this, we use a slag pot, where molten metals and oxides are mixed. The oxides help produce titanium when the molten metals cool and solidify. In this way, titanium chloride (TiCl4) may be manufactured.

TiCl4 is necessary for the production of titanium alloys. Titanium's atomic bonds give it superior strength to steel and other metals. Construction of aircraft and automobiles are two more industrial applications for TiCl4.

Accurate And Reliable CNC Milling Services

The backbone of AS Innovation Company is AS PRECISION, a CNC precision components machining facility. They are in the business of providing CNC machining services and precision metal parts. They understand the need to cater to a global clientele by stocking various CNC components.