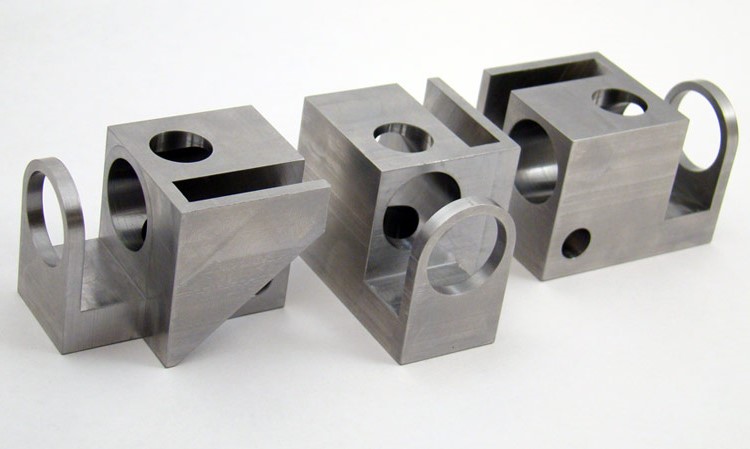

CNC Milling Services & CNC Milling Precision Parts

AS PRECISION is a professional in CNC Milling Service; we have Vertical Milling Machines, Multi-Axis Milling Machines, Machining Center Lathe; with such strong capability, we can bring customers flexible support on any kinds of product plan, small or huge orders are supported perfectly.

What Is CNC Milling Service?

CNC Milling Service is the process of milling machine which removes material from a solid blank to create a required/designed shape. The process is guided by designing and carried out by a machining program.

For parts with any special shape, including angled shapes, slots and channels, chamfers, holes, curves, and slide surfaces, “CNC Milling Service” is the best choice to carry out such various designing. CNC milling removes material quickly with high accuracy and brings a good surface finish.

CNC Milling is flexible in any shape, so it is convenient for small qty or big qty production. Especially it is good for prototyping starting without opening molds.