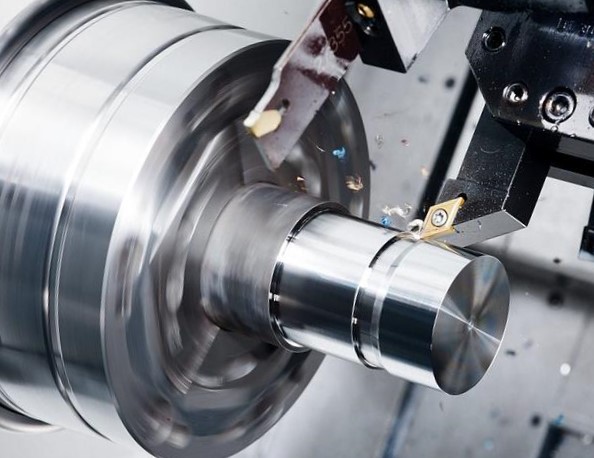

CNC Surface Finishing Services for Metal Parts

CNC finishing services, also known as surface finishing, are altering the surface of a material using different techniques to improve appearance and performance.

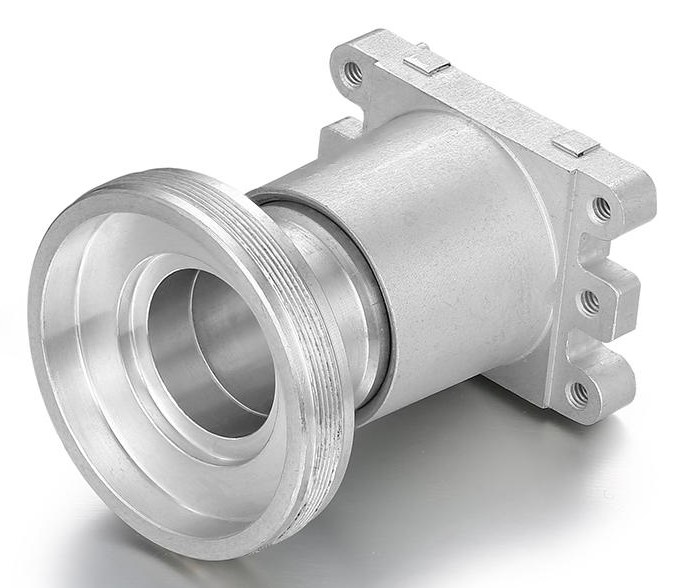

Examples include corrosion resistance, discoloration resistance, chemical resistance, abrasion resistance, hardness, changing electrical conductivity, and deburring or applying specific colors to machined parts.

It is usually through the chemical reaction of the workpiece surface or adding a layer of metal or non-metallic coating to the surface of the metal workpiece, and it can also clean the parts.

The “Metal Surface Finishing Services” is commonly applied on various CNC machining parts of aluminum, stainless steel, brass, and other materials.

With long-term experiences and a professional engineering team, AS PRECISION provides professional finishing machining services on work-piece according to customers’ requirements and obeying treatment compliance.

For different materials, different functions of work-piece, or different fields of industries, we can advise correct surface treatment solutions and workable finishing services to customers, make sure the R&D and Project direction is going on the right way.