The manufacturing process of custom aluminum milling is effective in producing assemblies and parts of greater quality at lower production costs. If you want to start machining aluminum parts, you might want to read this article that explores the benefits of custom aluminum CNC machining and outlines why you should use this service.

Advantages Of CNC Milling Aluminum

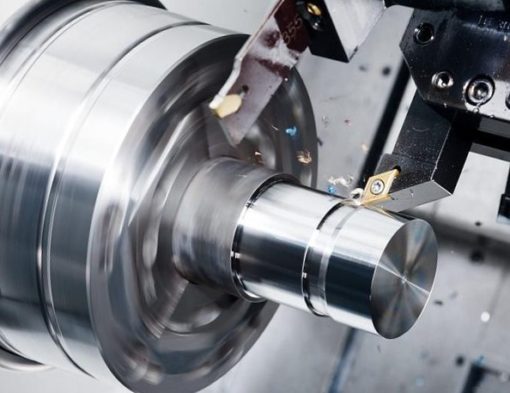

Aluminum, the most common metal on earth, is available in sheet, rod, wire, tube, and even MEK core forms. An aluminum ingot is chopped with a spinning cutter during the milling process to remove material. The benefits of CNC machining aluminum include:

Because it uses less energy and produces fewer pollutants than other production processes, aluminum CNC milling has a lower environmental effect.

Greater productivity: Aluminum CNC milling can create larger aluminum parts more quickly than conventional production techniques.

Modularity: Aluminum CNC milling's capacity to mass produce custom parts can boost output and quality.

Why Should Use CNC Milling Aluminum

The milling method is used to cut thin sheets of aluminum utilizing a number of rotating cylindrical dies. The dies create the intricate patterns in the metal, which may then be utilized to produce objects like parts for automobiles and airplanes. Aluminum CNC milling is used by the aerospace, automotive, and medical industries.

1.The milling of aluminum is an efficient and exact process. The ability of the machinery to perform precise machining and the skillful operators of the machinery enable this. Comparatively speaking to more traditional methods, custom aluminum milling provides the quick and affordable manufacturing of high-quality parts.

2.Custom aluminum machining enables the creation of unusual and complex designs. Contrary to conventional methods that require parts to be almost identical to one another in order to function, custom aluminum milling enables designers to make components with unique shapes and characteristics that are difficult or impossible to obtain.

3.Custom aluminum machining that's friendly to the environment. Custom aluminum milling has less of a negative environmental impact than other production methods. It can also be considered to be environmentally friendly because it uses less water and produces less garbage than other methods.

Conclusion

The many benefits of aluminum milling can be readily appreciated by a wide range of sectors. Whether it be for manufacturing or industry, aluminum CNC machining can provide the required accuracy and durability. If you're looking to start machining aluminum parts, AS PRECISION can be a great option for you.