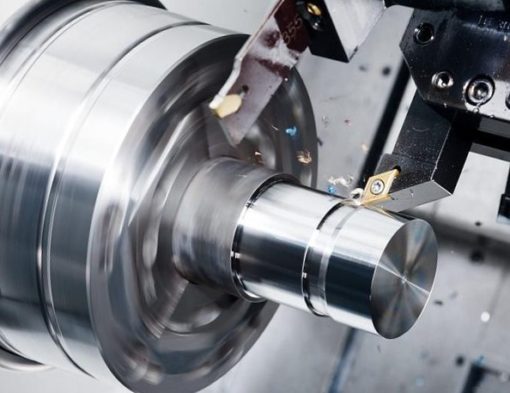

CNC milling is a manufacturing technique that uses computer-controlled machines to cut and surface metals and other materials. CNC milling produces accurate, highly repeatable results, enabling mass production. In today's world, with the advancement of technology, it is becoming easier and easier for businesses to invest in CNC milling manufacturing because of its extremely high ROI.

The benefits of CNC milling for manufacturing companies

CNC milling is a process of creating precise shapes from metal, plastic, or other materials using computer-controlled tools. The benefits of CNC milling for manufacturing companies include:

- Reduce the time and cost associated with producing custom parts.

- Precisely Controlled Manufacturing - Use CNC milling to quickly and easily manufacture parts without labor-intensive hand-manufacturing.

- Increased production efficiency – As production speeds increase, companies can reduce the time it takes to manufacture products.

The use of CNC machine tools

CNC milling can produce parts with high precision, high precision, and good repeatability. This makes it ideal for products that must meet specific tolerances or require a high level of quality control.

Using CNC machines, manufacturers can automatically make multiple copies of the same part without manual labor. This saves time and money and enables manufacturers to keep their production lines running at full speed.

CNC machine tools are widely used and can be used to manufacture a variety of products. They are ideal for manufacturing gears, bearings, and other parts that require precise geometric measurements.

Conclusion

If you are at all familiar with manufacturing, then you probably know CNC milling. This cutting-edge technology is used to produce high-quality parts quickly and efficiently, which is why many manufacturing companies are looking to invest. Then you should consider investing in a CNC machine kit from AS PRECISION.