CNC milling is the process by which computer-controlled machines use numerical control and 3D modeling to create parts. Milling manufacturers may use CNC milling because it is faster and more accurate than other types of manufacturing, such as machining or turning. If you are curious about what CNC milling is, read this blog to learn more.

What is CNC Milling Manufacturing?

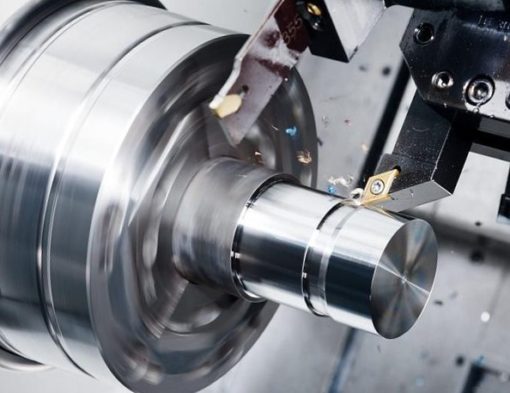

CNC milling is a cutting process that uses computer-controlled tools to create parts from a piece of material. It is often used in manufacturing processes because it produces precise, repeatable results. In addition, CNC milling is fast and efficient, making it ideal for high-volume production.

Benefits of CNC Milling Manufacturing

CNC milling is the process of making parts from a variety of materials using computer-controlled tools. The benefits of using this process in manufacturing include increased speed and accuracy, which in turn increases the production efficiency. In addition, CNC milling can facilitate the production of parts with complex shapes and intricate details. Some of the most common applications for CNC milling include automotive parts, medical devices, and consumer electronics.

The use of CNC milling machines in manufacturing

CNC milling machines are used in many different manufacturing industries, from automotive to aerospace. What makes these machines so valuable is their ability to make products by cutting parts of metal or other materials. The most common CNC milling machines are three-axis machines that can cut in three directions. This allows for more precise cuts and greater precision in the finished product.

Many factors go into choosing the right CNC milling machine for a manufacturing company. Some important considerations include the type of material that will be milled, the size and shape of the part being fabricated, and the complexity of the project. Many companies also use CNC milling machines to produce prototypes or small batches of items, rather than large batches. This provides projects with greater flexibility and faster turnaround times.

The use of CNC milling machines is becoming more and more popular in the manufacturing industry because they can achieve a high level of precision and precision in production. CNC milling machines are mainly divided into three types: rotary, linear, and hybrid.

Rotary CNC milling machines use a rotating barrel to create the cutting motion. They are best for complex designs that require a high degree of detail and accuracy. Linear CNC milling machines use a series of parallel axes to generate the cutting motion. They are great for more general tasks like cutting wood or plastic. Hybrid CNC milling machines combine the characteristics of rotary and linear machines to provide the best of both worlds.

Conclusion

CNC milling is a process that uses a computer to control the speed and direction of a cutting tool as it moves through metal or other materials. The technology can be used to produce parts with greater precision and less waste, thereby increasing the efficiency of factories and reducing the costs associated with producing products. So if you're looking for ways to improve your production process, consider incorporating AS PRECISION's CNC milling service into your strategy.