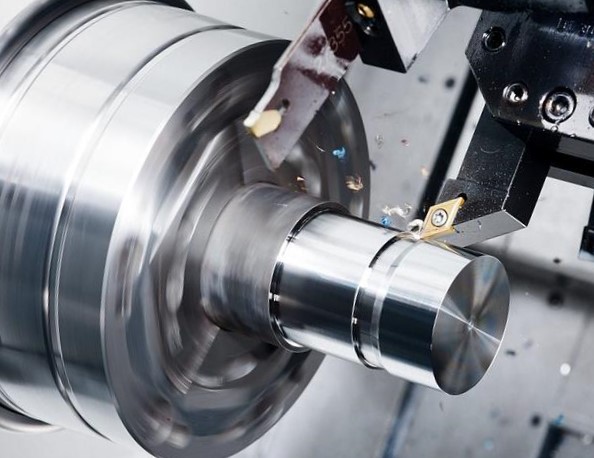

Milling parts are metal pieces that are created by a milling machine, which is a tool that can be used to remove metal. These machines can range from small, benchtop units to large industrial-grade machines. This article provides information on the different types of milling parts as well as their uses, whether they are found in industry or even in your home.

What are milling parts?

Milling parts are pieces of metal, plastic, or composites that are cut and shaped using a milling machine. The most common type of milling part is a screw, which is often used in manufacturing to produce screws, nuts, bolts, and other fasteners. Other types of milling parts include gears, bearings, and other moving parts.

Milling parts for construction

Applications of milling parts for construction are many and varied. From the simplest, such as screws and bolts, to the more complex, such as an entire engine block, milling parts can be used in almost any construction project. Milling parts can be made from a variety of materials, including metals and plastics. The type of material used will depend on the application and the desired quality of the finished product.

Some common applications for milling parts include:

-Screws and bolts: Mill screws and bolts from a variety of metals to create products that are tough yet lightweight.

-Nuts and bolts: Mill nuts and bolts from a variety of materials to create products with different strength ratings.

-Engine blocks: Mill engine blocks from a variety of materials to create parts that are strong yet lightweight.

-Gears: Mill gears from a variety of materials to create products with different speeds and torque ratings.

Conclusion

Mill parts using a CNC machine can be used for a variety of applications, such as manufacturing new parts for products or creating prototypes. By understanding the different types of milling and how they work, you can find the perfect machine for your specific needs. If you are interested in milling parts, contact AS PRECISION for more details.