The milling procedure is used to reduce the size of your titanium material. Titanium milling is a viable choice for low-volume production runs because of its lower price and the fact that it requires fewer heat sources than aluminum or steel milling.

The Milling Process Of Titanium: How Does It Function?

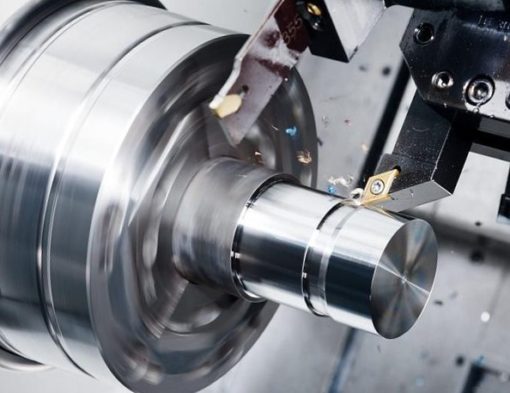

Titanium may be milled using a spinning tool to cut it into smaller pieces. Tiny, identical bits may quickly form into a real result from milling titanium. However, parts milled from titanium are well suited to rigorous space and road travel conditions. Hence this process finds widespread use in both fields.

To begin milling titanium, the metal must first be heated to the appropriate temperature. When the metal reaches this temperature, it becomes pliable, and the cutting process may begin. The metal is heated, then put on a mandrel that spins at high speed. The mandrel may rotate the tool more precisely while it slices the metal.

The metal must be cooled rapidly after being cut so that it may be molded into the desired form. There is less chance of a defect appearing in the metal once it has cooled. After the component has been allowed to cool, it may be machined into its final shape.

Milling Titanium Has Many Advantages

Titanium milling may shave as much as 75% off the time it takes to turn a hunk of raw material into a finished product.

Titanium milling may improve production efficiency because it can decrease item size and weight, two factors that contribute to overall manufacturing costs. For example, you may reduce your raw material and labor expenses this way.

Because of their improved strength and endurance, titanium-milled components are often of a better grade.

Specialized Precision Milling To Order

The primary operation of AS Innovation Company is AS PRECISION, a CNC precision components machining plant. They strive to become one of the greatest partners for global industrial businesses, precision metal part suppliers, and CNC machining service providers by concentrating on delivering a wide range of CNC precision parts to clients worldwide.

Manufacturers of machinery, equipment, vehicles, molds, electronics, telephones, dental practices, artificial intelligence developers, and the like may all benefit from their services. For example, provide Metal Surface Finishing services, including heating, grinding, polishing, anodizing, electroplating, coating, etc., on a wide range of materials, including aluminum, stainless steel, titanium, Carbon steel, brass, etc., as per client specifications.

Conclusion

The milling experts at AS PRECISION can tailor their services to fit your unique specifications. They've been doing this for a long time, so they know what has to be done. Additionally, they have a large variety of titanium tools and equipment, making it likely that they have what you need.