Custom aluminum milling is a manufacturing technique that works well to produce assemblies and parts of higher quality at reduced production costs. This article examines the advantages of personalized aluminum CNC milling and explains why you ought to employ this service.

Benefits of Aluminum CNC Milling

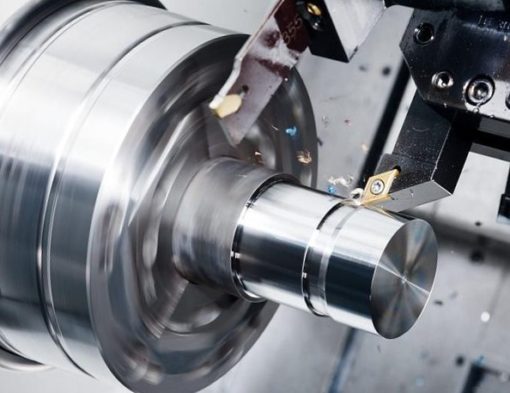

The most prevalent metal on the planet, aluminum may be found in sheet, rod, wire, tube, and even MEK core forms. A spinning cutter is used to cut an aluminum ingot in the milling process to remove material. The advantages of aluminum CNC milling include:

- Aluminum CNC milling has a lower environmental impact than other manufacturing methods because it requires less energy and emits less pollution.

- Greater productivity: Compared to other production methods, aluminum CNC milling can produce larger aluminum parts more quickly.

- Modularity: The ability to mass create bespoke parts with aluminum CNC milling can increase productivity and quality.

Why should you use aluminum CNC milling?

Thin sheets of aluminum are cut using a series of revolving cylindrical dies in the process known as milling. The detailed patterns in the aluminum are made by the dies, which may then be used to make items like auto and aviation parts. Medical, automotive, and aerospace industries all use aluminum CNC milling.

Aluminum milling is a quick and precise procedure. This is made possible by the equipment's capacity for precise machining and the knowledgeable users of the machines. Custom aluminum milling enables the speedy and cost-effective production of high-quality parts compared to more conventional processes.

Unique and intricate designs are made possible through custom aluminum milling. Custom aluminum milling enables designers to produce components with distinctive shapes and features that are challenging or impossible to obtain, in contrast to conventional methods that necessitate parts to be quite identical to one another to work.

Environmentally friendly custom aluminum milling. The environment isn't negatively affected by custom aluminum milling as much as it is by other production processes. Because it consumes less water and generates less waste than other methods, it can even be seen as environmentally benign.

Conclusion

A wide range of industries can profit greatly from aluminum milling's various advantages. Aluminum CNC milling can offer the necessary accuracy and sturdiness for any purpose, whether it be in manufacturing or industry. I hope AS PRECISION can fill your order for the appropriate aluminum CNC milling service.