CNC milling involves applying a specific design to produce a good or component with the specified size and form. Its benefits include affordability, adaptability, great corrosion resistance, and a beautiful finish when anodized.

What is aluminum CNC milling?

Aluminum is removed from a solid state by being cut into little pieces during the milling process. This can be done with the aid of cutting and grinding equipment and is useful for several tasks, such as producing parts, patterns, or stencils, as well as carrying out other operations that call for tiny pieces of aluminum.

Thin sheets of aluminum are cut using a series of revolving cylindrical dies in the process known as milling. The detailed patterns in the aluminum are made by the dies, which may then be used to make items like auto and aviation parts. The strength, flexibility, and low weight of aluminum CNC milling are only a few advantages. Medical, automotive, and aerospace industries all use aluminum milling.

Compared to other techniques, milling aluminum has numerous advantages, including its versatility and capacity for exact outcomes. Additionally, aluminum milling has numerous uses, which makes it a preferred option for businesses all over the world.

Aluminum can seriously harm the workpiece when it is cut. A specific method for removing material by grinding with spinning tools is called aluminum milling. In comparison to other machining methods, using aluminum milling has several advantages, such as less tool wear, decreased machining time, precise control of the completed product, and enhanced production.

Applications for aluminum CNC milling

Everywhere you look, aluminum components may be found in a variety of sectors, including consumer and computer electronics, automotive, aircraft, industrial gear, and equipment. The following are the principal uses for milling aluminum:

- Vehicle parts (lightweight provides a high strength-to-weight ratio).

- Aerospace enclosures, brackets, and other parts that need to provide lightweight yet the heavy-duty capacity

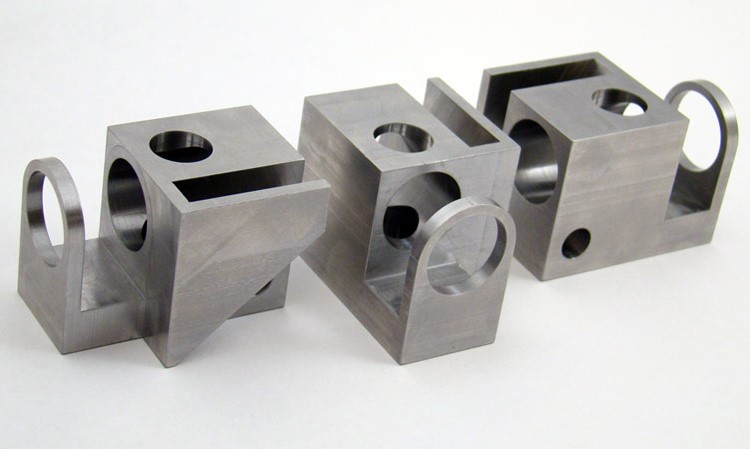

- A variety of different components for industrial machineries, such as clamps and calipers.

- For panels, consoles, knobs, enclosures, and other applications in consumer and computer electronics.

Conclusion

Aluminum may be used to make a variety of goods through the CNC milling process. The advantages of employing this approach include the capacity to generate large volumes of customized products quickly and the ability to personalize products. Everything from medical equipment and food packaging to parts for aircraft and vehicles can be milled out of aluminum. Aluminum milling from AS PRECISION can be the ideal choice for you if you're seeking a universal manufacturing technique.