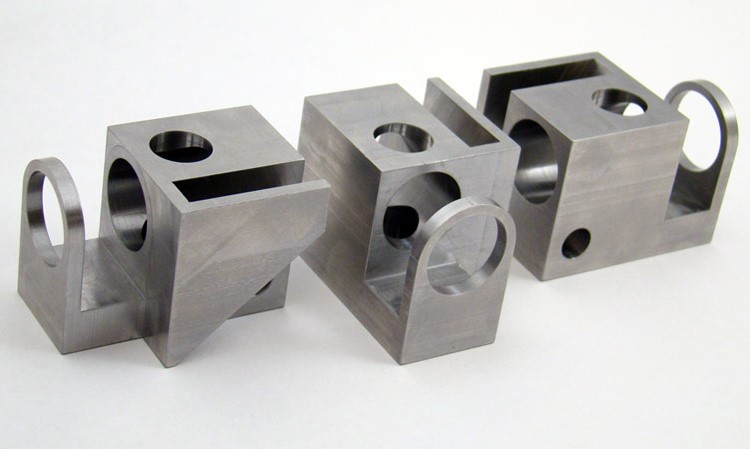

CNC milling, the process of cutting complex designs into materials such as metal, plastic, etc., uses CNC machines. These machines are programmed with digital instructions from CAD programs to make precise cuts. The benefits of this technology include faster production times, high-quality results, and lower costs.

Benefits of CNC Milling

- CNC milling can save you time and money.

CNC milling is a technique that can drastically reduce the time it takes to manufacture a product. This is because CNC milling machines can quickly and accurately cut out parts of the design. This enables you to create products faster and at a lower cost than traditional manufacturing methods.

- CNC milling can increase your productivity.

CNC milling can help you make more precise cuts, increasing your productivity. This means you can produce your product faster without wasting time and resources in the process.

- CNC milling can reduce your manufacturing cost.

CNC milling can also help you reduce manufacturing costs by allowing you to use advanced machines and materials. This means you save on the initial investment and ongoing operating costs of your plant.

- CNC milling can improve the quality of your products.

CNC milling also helps improve product quality by allowing you to better utilize precise data acquisition systems and motion control systems. This means you will be able to produce higher quality products with less effort

Types of CNC machine tools

When you think of CNC machines, you probably think of large, bulky machines located in factories or workshops. But this is only one type of CNC machine. There are two main types of CNC machine tools: horizontal milling machines and vertical milling machines.

Horizontal milling machines are generally smaller and more compact than vertical milling machines. This is because it works on a smaller scale. It can also be used to make parts narrower than the width of the machine.

Vertical milling machines are larger and more powerful than horizontal milling machines. It can also be used to make parts wider than the tool width. However, it is not good at making narrow parts. Both machines have their advantages. For example, horizontal milling machines are better at making parts with straight edges. On the other hand, vertical milling machines are better at making parts with complex shapes or angles.

Conclusion

CNC milling is a powerful tool. Not only does it reduce the time and effort required to produce parts, but it also increases the precision and precision of your product. As such, CNC milling is an important investment for businesses of all sizes. Start ordering on AS PRECISION today!