Industrial design is continuing to evolve, and one of the ways that it has done so is with the introduction of CNC turning parts. Find out what these parts can do for you in this article, and how they might be able to improve your business right now!

What are CNC Turning Parts?

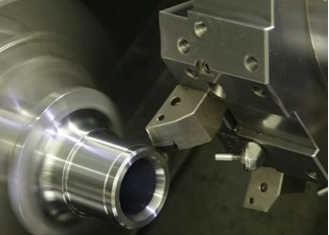

CNC turning parts are pieces of metal or plastic that have been shaped by a computer-controlled milling machine. The parts can be used in many different applications, including manufacturing and engineering. CNC turning parts can be made from a variety of materials, including aluminum, brass, stainless steel, and plastic.

Applications of CNC Turning Parts

We have already discussed the benefits of CNC turning parts, but what can we do with them? Here are a few examples:

-Small parts turn quickly, allowing for high production rates;

-Parts can be customized to specific needs;

-Parts can be made using multiple materials and finishes;

-Parts can be 3D printed.

Advantages of CNC Turning Parts

-Precision: With a CNC turning part, the geometry is always exact and no sanding or finishing is necessary.

-Speed: CNC Turning parts can be made quickly and easily, oftentimes with little to no human intervention.

-Design Flexibility: With CAD software, designers can create complex designs that can be easily turned into reality with a CNC Turning part.

-Repeatability: With consistent quality control, CNC Turning parts can be produced with high accuracy and reliability.

Conclusion

CNC turning parts offer a versatile way to manufacture products that are often difficult or expensive to produce using traditional methods. With the right software and hardware, you can quickly and easily turn any design into a 3D part. This opens up many possibilities for product customization and manufacturing efficiencies that can improve your bottom line. If you're interested in learning more about how CNC turning parts can help your business, be sure to check out the website of AS PRECISION!