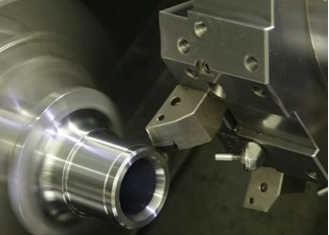

CNC turning is a process that uses computer numerical control and machine tools to position parts of the workpiece. It can be used in many different areas, from aerospace engineering and automotive design to jewelry manufacturing.

What is CNC Turning?

CNC turning is a process that uses computer-controlled tools to create parts from a variety of materials, including metals, plastics, and composites. It has many applications in industry, including manufacturing, aerospace and defense, and medical equipment.

CNC turning has become an increasingly popular way to make parts for products such as cars and airplanes due to its precision and high resolution. This precision is achieved through the use of computer-controlled cutting tools that are machined to very precise tolerances. The result is parts that are almost always exactly the right size and shape.

Benefits of CNC Turning

There are many benefits to using CNC turning for manufacturing. Some of the benefits include:

-Increased Productivity: With increased productivity, companies can reduce their manufacturing costs by producing more products with less manpower.

-Reduced Waste: Manufacturing processes that use CNC turning are more efficient and produce less waste, which can reduce environmental concerns.

-Reduced Maintenance Costs: CNC turning machines are easier to maintain and require fewer personnel to operate than traditional manufacturing processes. This saves companies on both the upfront and ongoing costs of maintenance.

-Increased Quality: The precise accuracy of CNC turning machines results in higher quality products than those produced through other manufacturing methods. This improves customer satisfaction and increases sales revenue.

Conclusion

The future of manufacturing is looking very bright. With the advent of CNC turning, manufacturers are now able to produce high-quality products faster and with less waste. If you're interested in learning more about CNC turning or exploring its potential as a part of your manufacturing business, be sure to contact AS PRECISION today!