The process of CNC milling involves numerical control, 3D modeling, and computer-controlled machinery to produce parts. Because CNC milling is quicker and more accurate than other manufacturing processes like machining or turning, CNC milling companies may choose to employ it. Read this blog to find out more about CNC milling if you're interested.

What exactly is CNC milling?

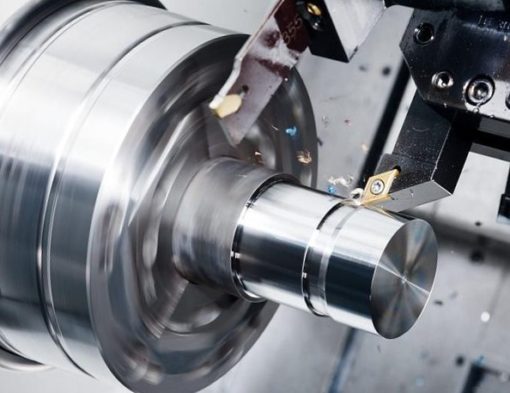

CNC milling is a process that uses a computer numerical control (CNC) machine to create parts from a solid block of material. The machine uses a series of cutting tools to create intricate and detailed shapes out of the material. This process is often used in manufacturing to produce complex parts quickly and accurately.

There are several types of CNC machines, but all work on the same principle. A feedstock enters the machine at one end, and the desired part or piece emerges at the other. The CNC machine uses several coordinates to control the position of the cutting tools, which means that it can create any shape or design you can think of.

CNC milling machines

Automobile and aerospace manufacturing sectors among many others employ CNC milling machines. The capability of these devices to produce goods by cutting components made of metal or other materials is what makes them so important. Three-axis milling machines, which can be cut in three directions, are the most popular type of CNC milling machines. This enables more accurate cutting and a more exact final product.

For a manufacturing organization, there are numerous considerations when selecting the ideal CNC milling machine. The kind of material that will be milled, the part's size and shape, and the project's intricacy are a few crucial factors to take into account. Additionally, a lot of businesses make prototypes or short runs of goods rather than bulk orders using CNC milling machines. Projects benefit from more flexibility and quick turnaround thanks to this.

Because they can reach a high level of precision and precision in production, CNC milling machines are being used more frequently in the manufacturing sector. The three primary categories of CNC milling machines are rotary, linear, and hybrid.

Conclusion

In the process of CNC milling, a computer is used to regulate the speed and path of a cutting tool as it passes through metal or other materials. With the help of technology, parts can be produced with better precision and with less waste, improving factory productivity and lowering production costs. So, if you're seeking strategies to enhance your production process, think about a CNC milling company AS PRECISION in your plan.