Using computer-controlled machinery to cut and surface metals and other materials is a manufacturing process known as CNC machining. CNC milling enables mass production by delivering precise, highly reproducible outcomes. Due to its extraordinarily high return on investment, CNC machining parts suppliers are becoming more and more popular in the modern world as a result of technological improvement.

5 advantages of CNC machining from making parts

Precision CNC machining offers many advantages over traditional machining methods, including increased accuracy and efficiency. Here are five advantages of precision CNC machining is becoming increasingly popular:

- Precise machining results in tighter tolerances, which can improve the quality of a product.

- Reduced part costs: By using precision CNC milling, manufacturers can achieve greater accuracy and control over their manufacturing process, which can result in lower part costs.

- Increased production speeds: With precision CNC milling, machines can be programmed to move at high speeds, which can boost production rates significantly.

- Improved surface finishes: By precisely cutting parts from a solid block of material, surface finishes can be improved dramatically – even on complex parts.

- Reduced manufacturing time: Precision CNC machining can shorten the time it takes to produce a product by allowing for more accurate and efficient design processes.

Using CNC machine tools

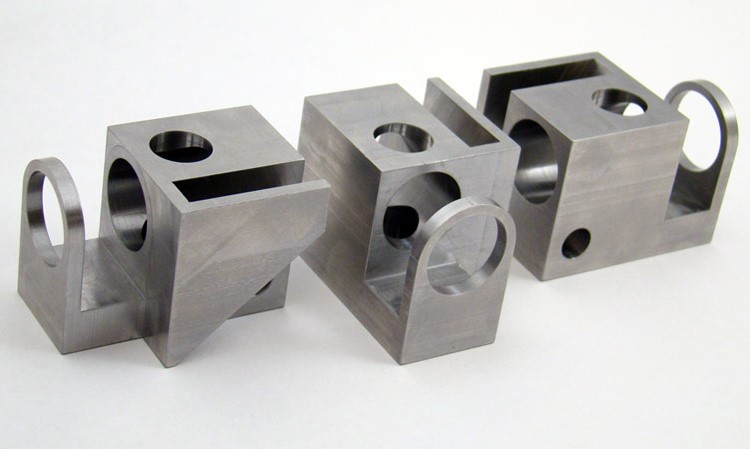

CNC milling can create components with excellent repeatability, high precision, and high precision. This makes it perfect for goods that have strict tolerance requirements or necessitate a high degree of quality control.

Manufacturers can use CNC machines to automatically produce numerous copies of the same part without using physical labor. As a result, firms can keep their manufacturing lines running at full capacity and save time and money.

CNC machine tools are frequently employed and can be utilized to produce a wide range of goods. They are perfect for producing bearings, gears, and other components that need exact geometric specifications.

Conclusion

CNC milling is likely something you are familiar with if you have any manufacturing experience. Many industrial organizations are looking to invest in this cutting-edge technology because it can manufacture high-quality parts fast and effectively. Then you want to think about a CNC machining parts supplier AS PRECISION.