You are undoubtedly already aware of stainless steel parts. This material is resistant to corrosion; it does not rust or corrode and does not need painting or plating. It's possible that you're not aware that there are two ways that the surface of stainless steel may be finished: brushed and polished. This article on the blog describes what these finishes entail for the project you are working on.

Finishing The Surface Of Stainless Steel Is Known As What?

Stainless steel is a sturdy metal that will not rust but may tarnish with time. Despite this, stainless steel is quite robust. The shine of stainless steel may be restored by polishing, which will keep it from tarnishing.

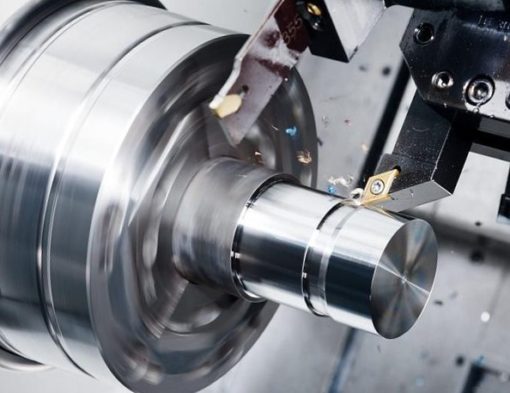

Finishing machining intentionally generates a surface layer with distinct mechanical, physical, and chemical characteristics of the substrate on the surface of the substrate. These differences may be caused by various factors, including heat, pressure, and chemical reactions. The purpose of the surface treatment is to fulfill the particular functional needs of the product, such as its corrosion resistance, wear resistance, decoration, or other requirements.

Grinding the surface mechanically, subjecting the surface to chemical treatment, subjecting the surface to heat treatment, and spraying the surface are the most frequent surface treatment procedures for metal castings.

Advantages Of Having a Surface Made Of Stainless Steel

Stainless steel is a metal used often in commercial and industrial settings due to its durability and resistance to corrosion. It offers several advantages, some of which you may not be aware of, such as its resistance to corrosion and its capacity to keep its shine. Using surfaces made of stainless steel has several advantages, including the following:

Stainless steel does not rust as other metals do, but no of the conditions in which it is stored, it will not rust over time.

Additionally, it is quite simple to clean and restore its like-new appearance; you only need dish soap and water.

Stainless steel from AS PRECISION is quite good at keeping its luster; because of this, it is an excellent choice for settings where you want something strong yet professional appearance.

Conclusion

If you want an alternative that can be clear coated, the pieces made of stainless steel will be your finest choice.

In addition to being resistant to corrosion, the steel used to make stainless steel also contains a very high percentage of stainless in its composition. This characteristic of the steel surface indicates that it is impervious to stains and other types of marks. Additionally, it is often employed in applications that need high accuracy, such as in surgical equipment and components for aeronautical vehicles.