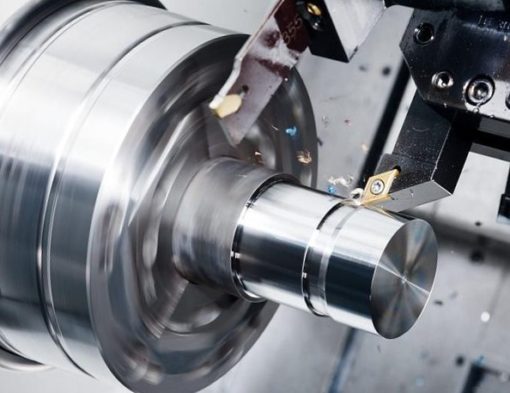

When designing your parts or prototypes, you need a machine that delivers precision, speed, and consistency. CNC milling parts are the ideal solution because they can produce almost any shape at high speed.

What are milled parts?

Milled parts are metal, plastic, or composite materials that are cut and shaped with a milling machine. The most common milled part is the threaded rod, which is often used to make screws, nuts, bolts, and other fasteners. Other types of milled parts include gears, bearings, and other moving parts.

The applications of milled parts

The applications of milled parts for construction are varied. From the simplest screws and bolts to more complex ones such as entire engine blocks, milled parts can be used for almost any construction project. Milled parts can be made from a variety of materials, including metals and plastics. The type of material used will depend on the application and the desired quality of the finished product.

Some common applications for milling parts include:

- Screws and Bolts: Grind screws and bolts in a variety of metals to create strong and lightweight products.

- Nuts and Bolts: Grind nuts and bolts of various materials to create products with different strength levels.

- Engine Blocks: Engine blocks are ground in a variety of materials to create parts that are both strong and lightweight.

- Gears: Gears of various materials are ground to create products with different speed and torque ratings.

Conclusion

If you're looking to reduce waste in your manufacturing process, or you just want to increase the efficiency of your production line, CNC milled parts from AS PRECISION may be a great choice for you. By using precision machining techniques and cutting-edge equipment, you can produce parts with precise specifications—meaning significantly less waste involved in the manufacturing process. Additionally, by producing parts this way, you can speed up processing times and reduce costs associated with traditional manufacturing processes.