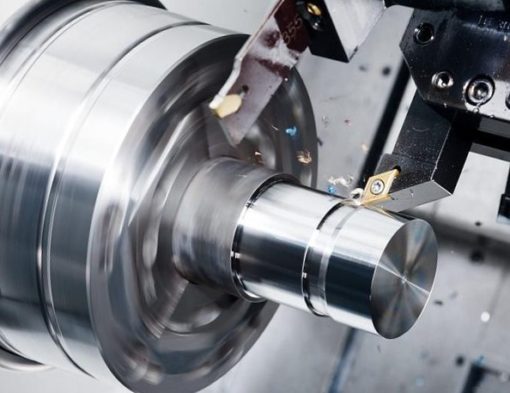

In the manufacturing process known as CNC milling, the material is cut from a model or other three-dimensional object to produce the desired product. It is a cutting-edge machining technique th several benefits, particularly useful in high-precision production due to its ability to create intricate forms and designs with little waste. So keep reading to discover more about custom machine services if you're seeking for a means to save costs while still keeping the greatest possible quality and precision!

What advantages do custom machining services offer?

By chopping solid material into tiny bits, milling is the process of creating three-dimensional objects. It can be used to make intricate patterns and shapes, as well as parts for things like toys, bicycles, and automobiles.

The benefits of using a CNC milling machine are numerous. First off, the end product will be of superior quality to work done by hand because of the precision and accuracy with which it can be cut. Two, by creating goods in batches, you can save time and money because machines can swiftly make big batches of parts. The versatility of CNC milling machines allows you to select a product that meets your requirements because it may be utilized for a variety of different activities. Contact us right away if you're interested in finding out more about how CNC milling machines might help your company.

How to begin custom machining?

Cutting apart a piece of material using a revolving tool is known as a milling service. CNC milling can be used to create components for items like vehicles, medical equipment, and airplanes. There are numerous varieties of mills, each with distinct benefits.

Before beginning milling, you must select the best machine for your job. Manual, automated, and CNC milling machines are the three basic varieties. The simplest sort of milling cutters is manual milling cutters, which you must manually operate. You only need to slide the workpiece onto the spindle with automatic milling machines since sensors manage the cutting activity. Precision projects benefit greatly from using CNC milling machines, which are the most sophisticated sort of milling machines that employ a computer program to control the cutting activity.

Conclusion

The procedure of CNC milling is very beneficial for production. CNC milling can speed up the manufacturing process, resulting in a significant improvement in production efficiency. Additionally, you can swiftly and simply make customized components or goods with custom machining services. Get in touch with AS PRECISION right away to learn more if you're interested in exploring these options further.