CNC milling is a machine tool that uses a computer to mill, drill, or shape material by numerical control. It can be programmed to do the job with minimal human involvement. As technology advances, CNC milling has the potential to become the only way to manufacture large quantities of products. Follow us as we explore the history and evolution of CNC milling in the United States.

What is CNC milling?

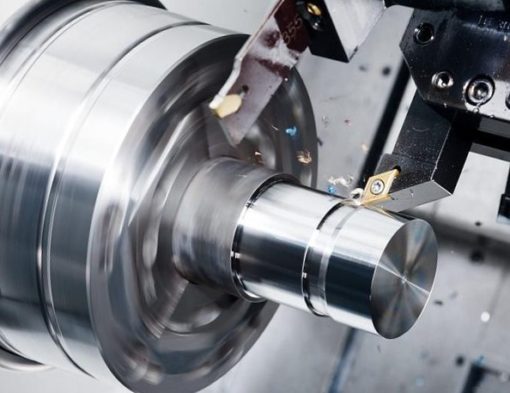

CNC milling is the process of using a computer to control the movement of a machine tool. This process is used to create parts or products from various materials. CNC milling is a very versatile process that can be used to manufacture a wide variety of products. It can be used to make parts for cars, bicycles, machines, and even houses.

CNC milling provides the flexibility to machine any shape, making it easy to produce large or small batches. Especially suitable for starting prototyping without opening a mold.

One of the greatest benefits of CNC milling is that it is very precise. This precision allows precise measurements, which makes it a very reliable process. CNC milling is also fast and easy to use. This means it can be used to create parts quickly and easily.

The type of material used to craft the item

Metal is a tough and durable material, ideal for projects that require durability. You can create intricate designs using CNC milled metalworking as well as very intricate details.

Aluminum can be easily formed into the specified shape and finished quickly. The most common types of extruded aluminum are aluminum 6061 and 6063 alloys, which can be used for batch CNC machined parts.

Conclusion

If you're interested in learning how to mill your parts, this guide is for you. In it, we'll cover everything from the basics of CNC milling to more advanced techniques and techniques. Hopefully, with this guide, you will gain an in-depth understanding of what CNC milling is and how to use it to make your job easier and faster. So, if you are ready to start your project, please contact AS PRECISION!