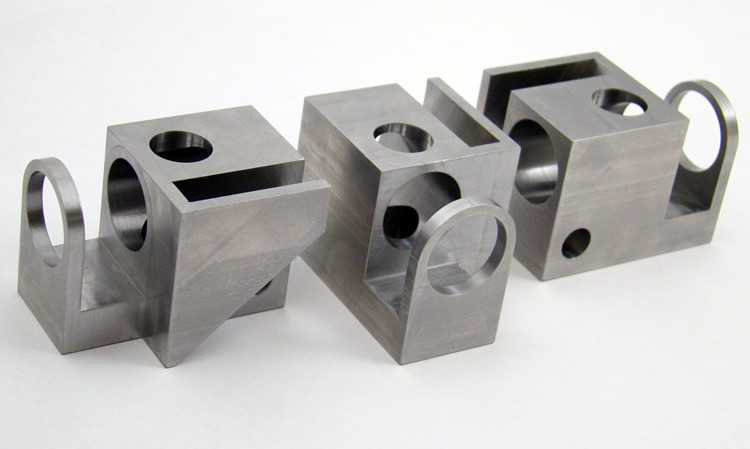

CNC manufacturing creates many of the precise parts we use in all many products, from automobiles to items aboard rockets traveling to outer space. These precise parts are generally created using advanced technology, computer-aided designing, and fabrication to meet all specific customer needs with the best precision. Of the factors used to inspect the quality of the CNC parts, material hardness is essential, just as much as part size and tolerance.

Different Standards of Measuring the Hardness of the Precise Parts

There are many ways to measure the different hardness levels of the materials being used to create precision parts. Most premium CNC machining service providers will integrate one of the four that are well known in the industry, including:

- HRC - The Rockwell hardness test is typically used to measure indentation hardness for precise parts. This is done by using some form of indenter like a diamond tip and then applying a minor amount of load into the material. The result of HRC measurement is a number that lets manufacturers know how hard the material is.

- HB - The Brinell Test is similar to HRC in that it also measures the indentation hardness of any material. In this case, a predefined force is applied to a steel ball to create an impression. The size of the indention under a microscope results in the hardness of the material.

- HV - Vickers Procedure involves a unique unit of hardness determined by the Vickers Pyramid Number. An indenter is also used, but the sample has to have a flat surface for a more accurate result.

- HL - This is the only dynamic test method that tests the impact velocity of a moving body and how quickly it reforms to determine hardness.

The Wide Application of High-Hardness CNC Machining Parts

While all precise parts serve a particular purpose, high hardness parts have become more popular over the past few years due to their increased service life. A high hardness part resists abrasion and can be subjected to high frictional stress. Low hardness metals will deform under repeated frictional stress, leading to a dangerous situation.

Most clients looking for high-hardness precise parts contact CNC machining parts suppliers that can offer end products that are scratch resistant, rebound quickly from indentation, and are resistant to deformation during their intended use. While these parts can be more expensive, they tend to balance out upfront costs compared to maintenance or replacement expenses because of their long-lasting value.

Two Ways to Get High Hardness Machining Parts

There are two common methods to improve the overall quality and hardness of your next precise part order. These are:

- Start with High-Hardness Materials - Working with a metal or raw material that is already considered high in hardness from the different scales available will lead to an equally high hardness product. However, many of these materials are more challenging to turn and mill because they are not as pliable for processing.

- Apply Heat Treatment - Heat can be applied to many metal alloys, enhancing their physical properties, including hardness. By working with a slightly less hard material, you can turn and mill it to the form you wish and then apply heat treatments to enhance the microstructure so it becomes harder.

Choosing AS PRECISION for Your Precision Parts

Since 2005, AS PRECISION has been an industry-leading supplier of CNC precision parts and services. Our locations ensure a quality product that can update or improve your products on the global market. When you work with AS PRECISION, you get:

- Wide Range of Processing Services - We offer more than 50 engineers and hundreds of machines from prototyping to full-scale manufacturing. This allows us to fulfill practically any order that comes across our desks.

- Highly Accurate Products - We strictly follow the different tolerance requirements for the niche market or industry we are serving, with our highest precision reaching 0.002mm.

- Strict Quality Control - Every precise part that moves through our company encounters multiple steps of quality control. We take pride in our reputation for high standards and put safeguards in place to ensure a positive outcome.

- Satisfying Customer Service - Our professional team of sales and support staff works closely with each client. We listen closely to your needs and offer quality service – that is why we have such a high repeat and referral business rate.

- Fast Delivery -We work with industries that require quick delivery of precise parts to fulfill their own product line or achieve a critical benchmark in their production process. That is why we partner with local, national, and international shipping companies to ensure your products are delivered to you safely.

Wrapping Up

The next time you are seeking CNC machining services from one of the leading CNC machining precision companies, reach out to AS PRECISION. We are more than happy to consider your request and go into detail with our team so that all your needs are met to the best of our abilities. Our professionalism, experience, and technology produce reliable positive outcomes year after year.