Cutting, folding, or forming sheet metal are all parts of the metalworking process known as aluminum CNC milling. When it comes to how the material is cut, folded, or molded, there are numerous distinct techniques and procedures used for this kind of job. The goal of these techniques and associated best practices are discussed in this article.

Aluminum CNC Milling

Due to its strength and low weight, aluminum sheet metal is frequently utilized in aerospace and automotive applications. These characteristics make them perfect for lightweight yet incredibly strong components like aircraft wings and body panels.

Because aluminum is a delicate metal, special care must be taken to prevent damage during manufacturing. Aluminum sheets, for instance, may bend or distort if they are subjected to severe welding or cutting. Manufacturers frequently employ extremely accurate welding and cutting procedures to prevent these harmful impacts.

Benefits of aluminum CNC milling

Due to its various benefits over conventional metals, aluminum is a preferred material for metal manufacturing. Here are three benefits of choosing aluminum over other materials:

- Robustness. Due to its high durability, aluminum is ideal for making powerful and long-lasting items. Because it won't corrode or tarnish even in damp environments, it can be utilized in places where other metals are dangerous.

- Cost reductions. Aluminum is a great choice for items that need to be both economical and long-lasting because it is significantly less expensive than other conventional metals.

- Flexibility and lightness. Due to its small weight and flexibility, aluminum is perfect for items that need to be portable and simple to handle.

How are aluminum parts manufactured?

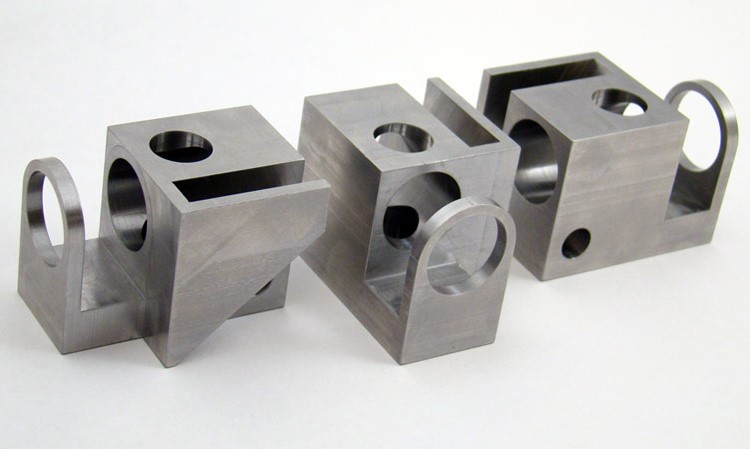

Aluminum parts must first be correctly shaped into the desired shape to be manufactured. Typically, this is carried out with the use of CNC milling machines or other industrial equipment. After the parts are created, they are trimmed to size and joined utilizing unique methods of welding. To help the metal components resist corrosion and other types of damage, a coating is applied last.

Conclusion

You should get in touch with AS PRECISION if you're looking for high-quality aluminum sheet metal fabrication. To ensure that your particular demands and objectives are met, our qualified team of experts can assist you in developing custom metal products. We will be able to produce goods that are both beautiful and useful thanks to our years of experience.