Do you need machining aluminum parts? Are you aware of the process? Learn more in this blog post that talks about what machining aluminum parts are and how it works.

What Is Machining Aluminum?

Aluminum is a popular material for manufacturing parts because it is strong yet lightweight. The metal can be machined using a variety of processes, including CNC and manual machining. CNC machining is the most advanced way to machine aluminum, but it can also be done manually.

The first step in machining aluminum is to cut the part to be manufactured. This can be done using various cutting tools, including plasma cutters and saws. Once the part has been cut, the next step is to remove any excess material with milling machines. This is done by grinding away at the part until it is smooth.

After the part has been milled, it must be annealed. Annealing softens the metal so it can be easily shaped with other tools. It also strengthens the metal so that it will not break under stress. Finally, finishing touches are added to the part's surface with polishing machines or sanders.

How Does Machining Aluminum Work?

Machining aluminum is a process that uses rotary or CNC machining to create parts from the metal. There are several steps in the machining process, and each has an impact on the end product.

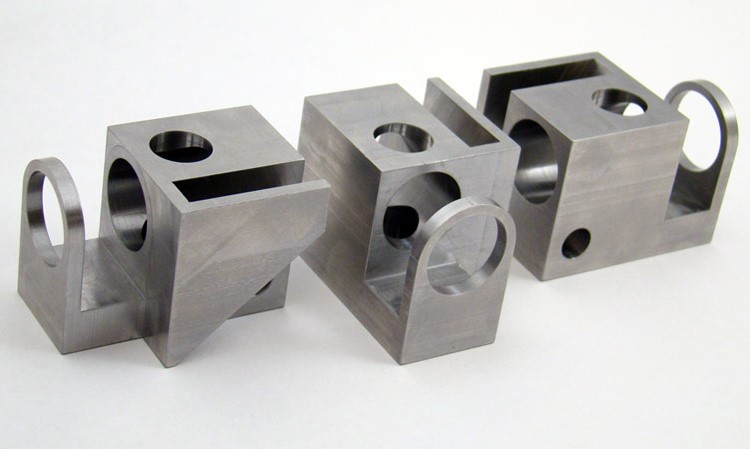

First, the part is cut out of an aluminum block with a saw or grindstone. The cuts are then precision machined using either vertical or horizontal milling machines. This produces detailed features of the part, such as curves and angles.

Next, the surface finish is applied using various processes like sandblasting or chemical etching. This gives the part its desired look and feel. Finallcoatings or clear coatings protect the parts from corrosion and other environmental factors.

Why Buy From AS Precision?

AS Precision is a leading supplier of aluminum parts and components. They offer machining services, including milling, turning, drilling, and tapping. The company's skilled machinists can produce high-quality parts quickly and efficiently.

Aluminum is a popular choice for manufacturing parts due to its lightweight properties and durability AS Prec. Mission offers various machining options for creating customized aluminum parts. Their experienced machinists can mill, turn, drill, and tap aluminum parts using standard tools and techniques.

AS Precision also offers a wide range of customization options for its customers. They can provide precise dimensions and tolerances for each part and additional features such as texturing or laser etching. This allows customers to create specific types of parts unavailable from other suppliers.

Conclusion

Suppose you're looking for top-quality aluminum parts that are easy to use, AS Precision is the perfect option. Their experienced machinists will help you create the perfect part quickly and easily.