Rapid prototyping is a manufacturing process that uses 3D printing technology to create prototypes of products that can be used in the early stages of product development. It’s becoming more and more popular, as companies are finding a way to reduce costs by skipping the prototype phase of product development.

What Is Rapid Prototyping?

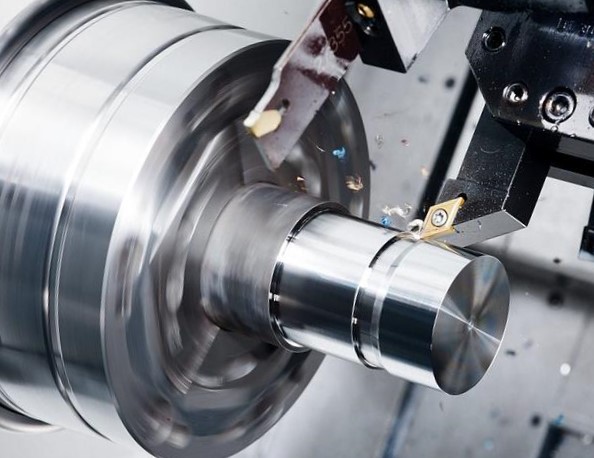

Rapid prototyping manufacturing allows you to create a working model of a product or design in just hours, not days or weeks. This technology uses 3D printing and other computer-aided design (CAD) tools to create a digital representation of a product or design. You can then use this model to test different designs and see how they would look and function before creating a real product. Rapid prototyping manufacturing is great for testing new ideas, finding problems with your designs, and reducing the time it takes to create a product.

How Does Rapid Prototyping Manufacturing Help Me?

Rapid prototyping manufacturing is a process that helps designers create physical models of a product or service quickly and inexpensively. This can help you test and iterate on design ideas more quickly, saving time and money.

Rapid prototyping manufacturing can also help you find errors in your designs before you produce physical products. By creating multiple copies of your designs, you can check for inaccuracies and inconsistencies in the construction of the product. If an issue is found, you can quickly fix it before producing any actual products.

Conclusion

Rapid prototyping manufacturing allows you to create a 3D model of a product or component, and then use it to fabricate the actual product. This can save you time and money, as you can quickly test variations of a design before committing to manufacturing them. If this sounds like something you could use in your business, contact AS PRECISION today!