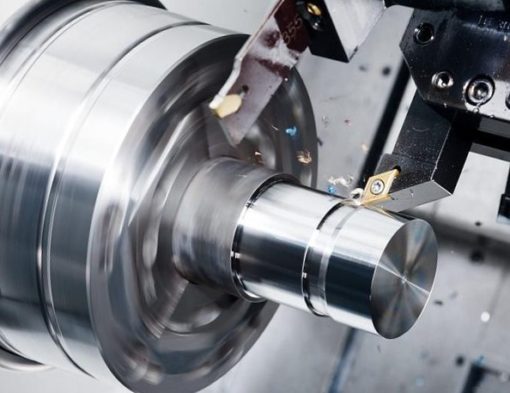

A CNC milling machine removes material from a solid blank to create the desired/designed shape. The machining program design directs and executes the process. With 17 years of experience and a reputation for excellence in the community, AS PRECISION are proficient in CNC milling services.

CNC milling machine types

Manual, semi-automatic, and automatic CNC milling machines are the three different varieties. It's crucial to select the kind that best meets your needs because each has benefits and drawbacks.

The earliest and still most prevalent type of CNC milling machine is the manual mill. They are often suited for small tasks because they require a lot of skill and experience to use. Manual grinders are more difficult to operate than semi-automatic grinders, although they still need some skill. The most common kind of CNC milling machines is automatic milling machines, which are excellent for big projects. Since they operate entirely automatically, you don't need to bother about any specifics.

CNC milling applications

CNC milling machines have a wide range of applications and can be used in numerous sectors. Just a few instances are shown below:

- Aerospace: Parts for aircraft and spacecraft are frequently made using CNC milling machines. Additionally, they are employed in the construction of airframes and engines.

- Automotive: CNC milling machines are frequently used to produce trucks and automotive parts. Wheels and headlights are examples of this.

- Manufacturing: CNC milling machines are also employed in manufacturing facilities to create components for goods like timepieces and metal products.

Conclusion

Precision pieces can be produced with CNC milling from a range of materials. You can produce parts with a high degree of precision and detail with CNC milling, which can enhance performance and lower production costs. If you want to grow your company and are thinking about investing in CNC milling services, AS PRECISION can be the best option for you.