Do you need custom aluminum parts to be made? Do you know how it works? This blog post explains what machining aluminum parts are and how it works so that you can learn more about it.

What Is Aluminum Machining?

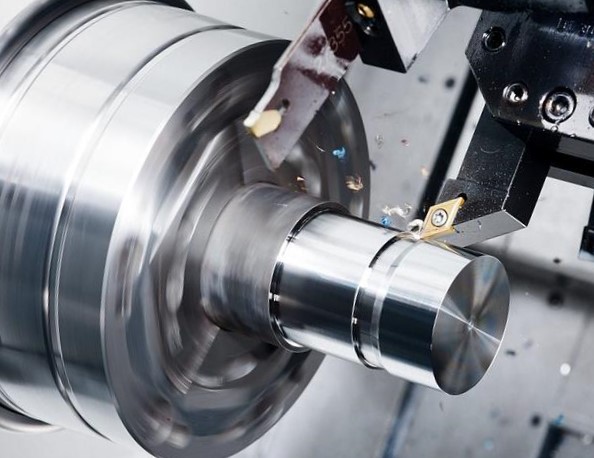

Aluminum is often used to make parts because it is strong and light at the same time. Several methods, such as CNC and manual machining, can shape the metal. The most advanced way to work with aluminum is with CNC machining, but it can also be done by hand.

The first step in making something out of aluminum is cutting the part. This can be done with plasma cutters, saws, and other cutting tools. After the part has been cut, milling machines remove any extra material. To do this, the part is ground down until it is smooth.

The part must be annealed after it has been milled. By annealing, the metal gets softer, making it easier to shape with other tools. It also makes the metal stronger so it won't break when stressed. Lastly, polishing machines or sanders are used to put the finishing touches on the part's surface.

How Does It Work To Cut Aluminum?

Aluminum can be used to make parts through a process called "machining." This can be done by using rotary or CNC machining. There are many steps in the machining process, and each one affects the final product.

First, a saw or grindstone is used to cut the part out of the aluminum block. The cuts are then cleaned up with precision milling machines that can be vertical or horizontal. This makes the part's details, like curves and angles, clear.

Next, a finish is put on the surface using sandblasting or chemical etching. This gives the part the look and feels that we want. Final coatings also called clear coatings, keep the parts from rusting and other environmental damage.

Why Should I Shop At AS PRECISION?

AS PRECISION is one of the best places to get aluminum parts and pieces. They can do milling, turning, drilling, and tapping, among other things. The skilled machinists at the company can make high-quality parts quickly and well.

Aluminum is a popular material for making parts because it is lightweight and strong. AS PRECISION offers different ways to machine aluminum to make custom parts. Their skilled machinists can mill, turn, drill, and tap aluminum parts using standard tools and methods.

AS PRECISIONalso gives its customers a lot of ways to make its products unique. They can give each part exact measurements and tolerances and extra features like texturing or laser etching. This lets customers make parts that can't be bought from any other supplier.

Conclusion

AS PRECISION is the best place to go if you want high-quality aluminum parts that are easy to use. Their skilled machinists will help you quickly and easily make the perfect part.